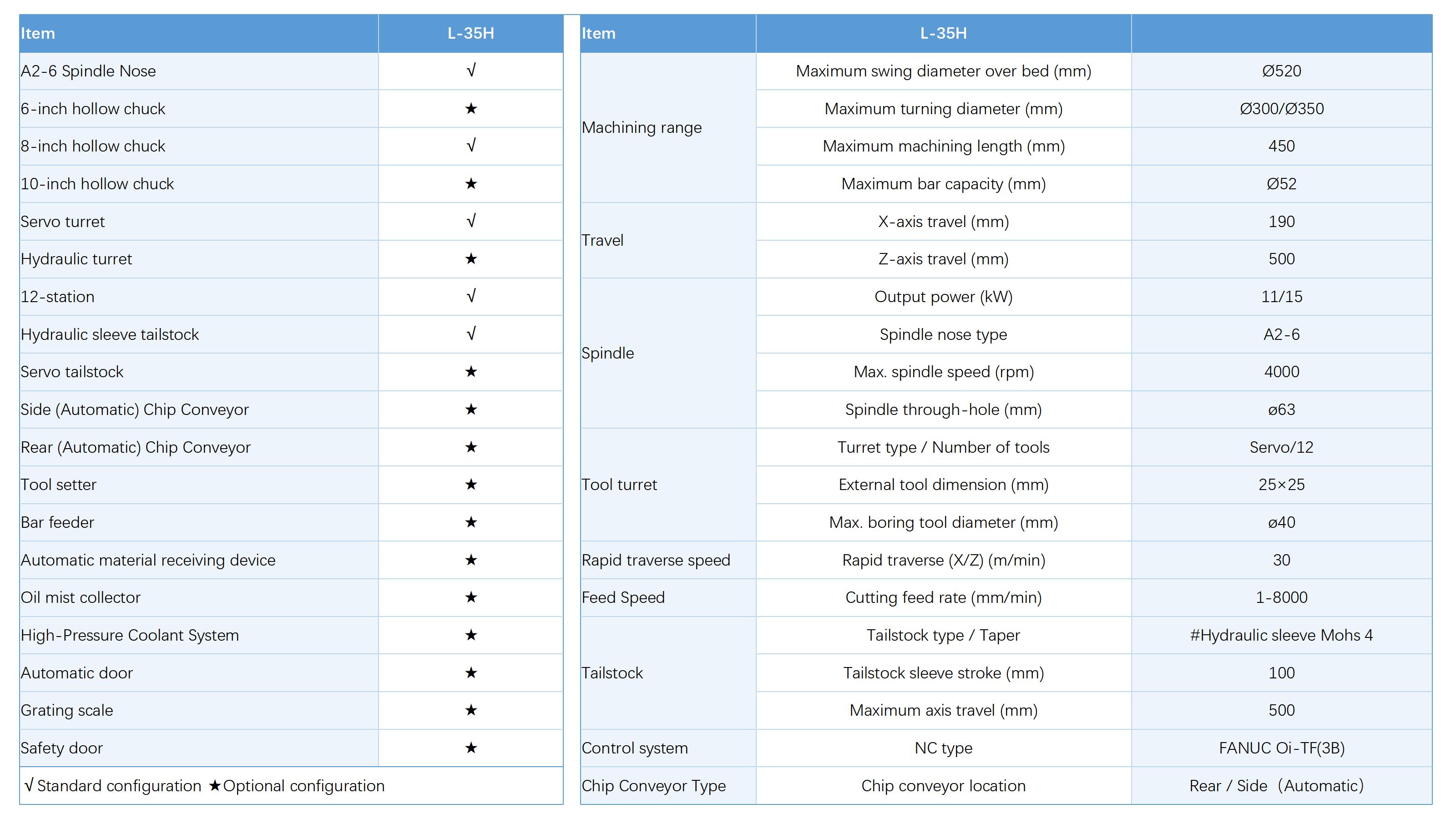

The L-35H is a high precision two-axis CNC lathe with semi-closed loop control, integrating mechanical, electrical, and hydraulic systems for turning-milling operations. | SPECIFICATIONS: √ 30° Monoblock Slant Bed √ 4000 rpm High-Rigidity Spindle √ 12-station hydraulic servo turret for fast and precise tool changes √ Machining Max. diameter Φ350 mm; Machining Max. Length 450mm √ Hydraulic sleeve-type tailstock for versatile machining of various workpieces

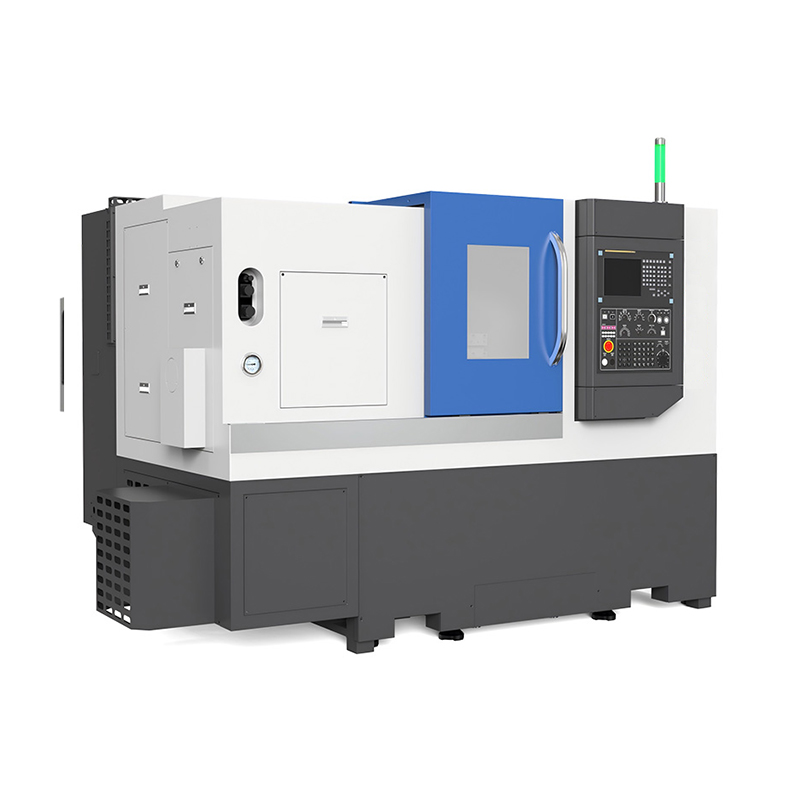

L-35H CNC Horizontal Lathe is a high-precision CNC lathe featuring a rigid two-axis turning system with semi-closed-loop control. This CNC turning center integrates mechanical, electrical, and hydraulic systems into a fully enclosed design with left-sliding door and right-mounted swivel operator panel for easy access.

As a multi-function turning and milling machine, it delivers exceptional rigidity, thermal stability, and cost-effectiveness. Built on a modular platform, the L-35H lathe supports CNC turning and milling operations in one setup, making it an ideal precision CNC machine tool for complex part manufacturing.

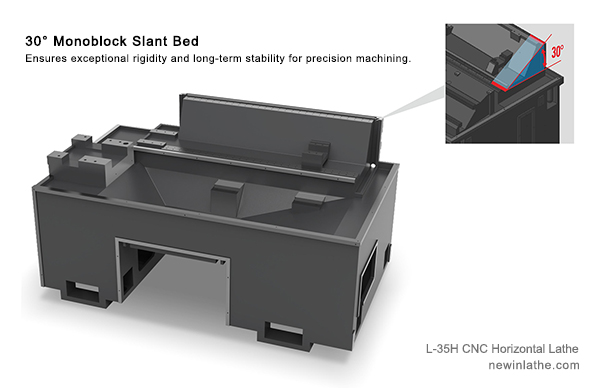

Ensures exceptional rigidity and long-term stability for precision machining.

| 30° Integral Slant Bed Construction | |

|---|---|

| • Features a 30° high-rigidity slant bed design with optimized rib layout through finite element analysis. • Castings undergo prolonged natural aging and secondary vibration aging treatments to eliminate internal stresses. • X/Z axes employ imported P-class 35mm roller linear guides with a wide-span design for superior load-bearing capacity. • Compact structure with a small footprint, ideal for space-efficient production layouts. |  |

Ensures high precision, high rigidity, and superior surface finish machining.

| Spindle System | Maximum Speed: 4000 rpm |

|---|---|

| • Front side: Equipped with imported P4-grade double-row cylindrical roller bearings and high-rigidity angular contact ball bearings. • Rear side: Utilizes imported P4-grade high-rigidity double-row cylindrical roller bearings. • Optimized spindle structure minimizes heat generation, paired with a high-torque motor. |

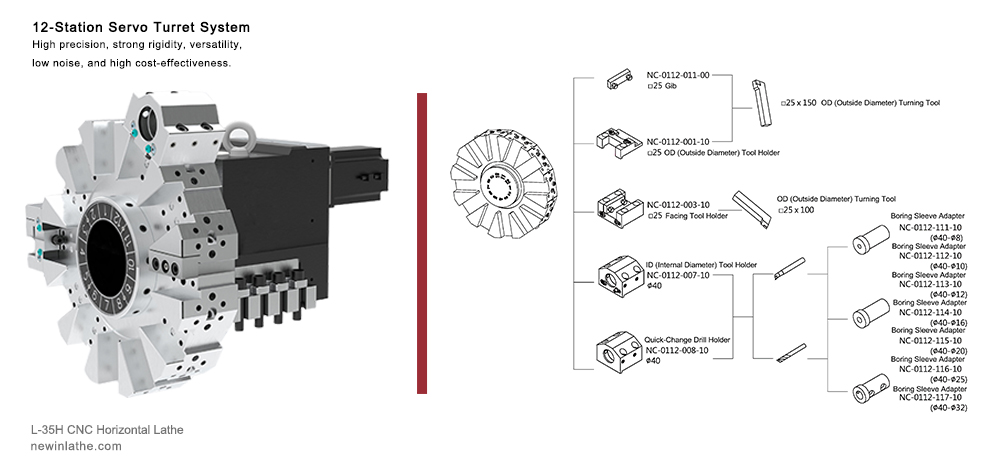

High precision, strong rigidity, versatility, low noise, and high cost-effectiveness.

| 12-Station Hydraulic Servo Turret (BMT45) |

|---|

| • Driven by a servo motor with an internal reduction mechanism for precise and reliable operation. • Hydraulic clamping provides high clamping force, suitable for heavy-duty cutting. • Adjacent tool station indexing time: 0.2 seconds; farthest station indexing time: 0.6 seconds. • Repeat positioning accuracy: ±2 arc seconds. • Curved-tooth indexing disc ensures larger contact area and enhanced rigidity. • Critical seals and bearings utilize premium Japanese or German brands. |

|

| • The X/Z axes are equipped with imported (C3-grade) large-diameter high-speed silent ball screws. An optimized pre-tension design effectively prevents thermal deformation and enhances positioning accuracy. Rapid feed rates reach 30 m/min for high efficiency, with positioning accuracy of ±0.003 mm. • The X/Z axes utilize imported 35 mm heavy-duty roller guideways, which offer excellent rigidity, dampen vibration, extend tool life, and deliver high precision, fast response, and long service life—meeting customers' long-term operational demands. |  |

| Hydraulic Sleeve-Type Tailstock | |

|---|---|

| • Designed with a wide-span hardened guideway structure for exceptional rigidity and high load-bearing capacity. • Its dovetail configuration ensures secure locking via the lower pressure plate. • Featuring a long sleeve stroke, hydraulic workpiece clamping with adjustable force accommodates the processing needs of diverse product types. |

| Featuring a high-rigidity structure and high clamping accuracy, its hardened and precision-ground sliding surfaces are directly lubricated. The wedge-type three-jaw chuck design is particularly suitable for clamping irregularly shaped workpieces. |  |

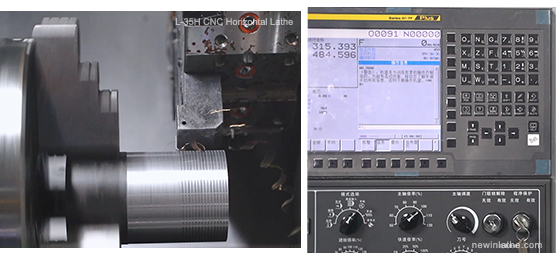

| Standard-equipped with the FANUC Oi-TF PLUS (3B) CNC system, delivering intelligent high-precision control and stable, reliable machining performance. |

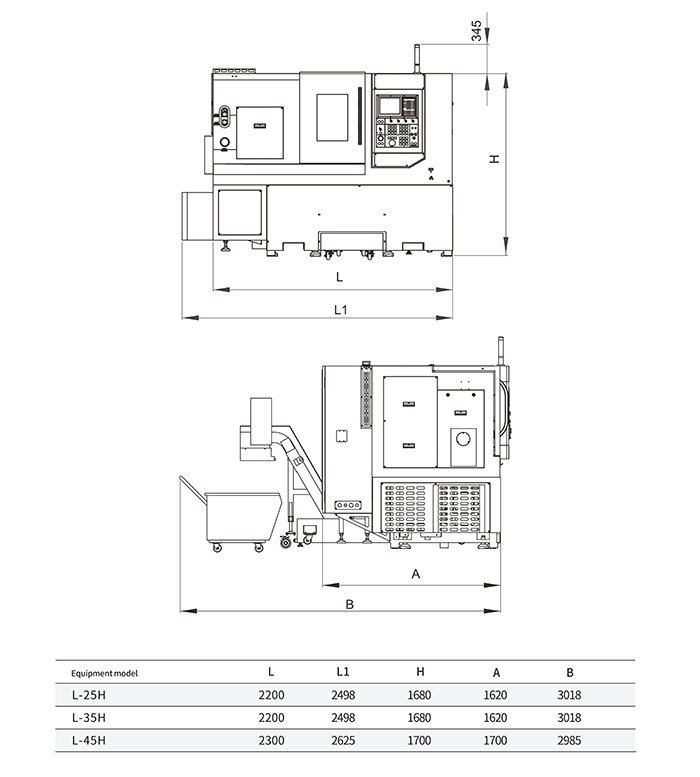

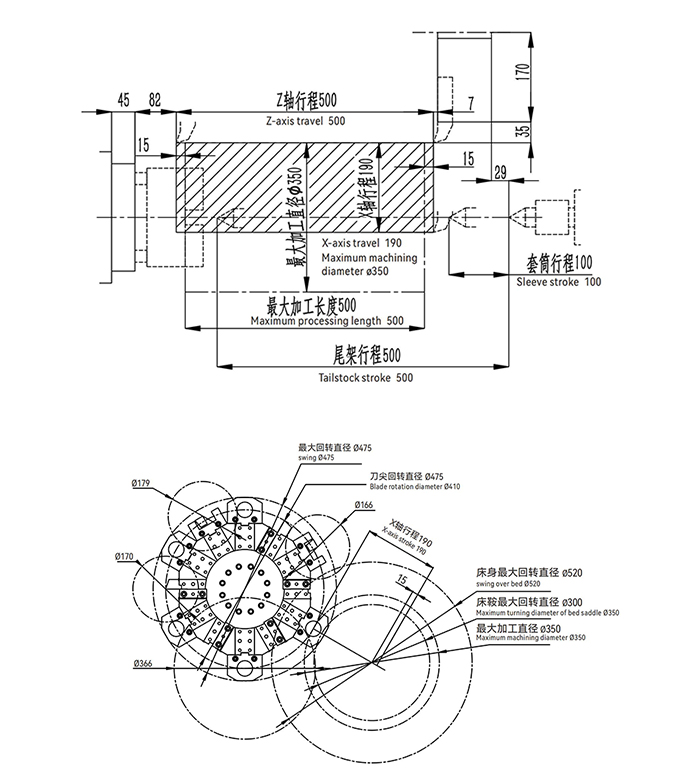

| External Dimension Diagram | Machining Capacity Chart & Machining Interference Diagram |

|---|---|

|  |

It is particularly suitable for small-to-medium batch, multi-variety flexible production of precision parts.

| • Aerospace Components: Shafts, Flanges | • Automotive Parts: Brake Discs, Drive Shafts |

| • Mold Components: Cores, Guide Pins | • General Precision Parts: Hydraulic Housings, High-Precision Bushings |